GOLDMAN Laundry Collar Press Yoke With DN 15 Steam Inlet

Manufacturer

LAUNDRY PRESS

Model Number

GMH-8(DN15)

Unit Weight

700 (315) lb(kg)

Size: 43.31*41.73*48.03in

Price: Minimum Order Quantity: 1set; Price: Negotiable; Delivery Time: 7-15 workdays upon receipt of deposit

Packaging & Delivery

Packaging

the package of industrial washing machine laundry equipment spare parts.Supply Ability

200 Set/Sets per Month laundry dryer machine parts.Shipping

Support Sea freight- Lead Tim -

- AQuantity(Pieces) [1-10] >10

- HK. Time(days) >30

Detailed Description

Laundry Collar Press Machine Yoke With Flexible Metal Mesh Padding DN 15 Steam Inlet

for hotel and laundry shops

For the customer seeking the best results possible. The TM-8 delivers consistent,high quality finishes every cycle.

It finishes the shirt collar and two cuffs in one operation and the yoke in a second operation. Built on our world-renowned heavy-duty UA frame with cast-iron "Y" piece,it will give years of trouble-free production.

Collar/Cuff presses form one part of a unique shirt system that increases productivity while reducing operating costs.

Features:

Top quality hydraulic absorber

Snug fitting head and buck.

Flexible metal-mesh padding ensures wrinkle-free pressing.

Technical Data:

| Compressed Air – NPT | 3/8" |

| Compressed Air Pressure – psi(bar) | 80(5.5) |

| Compressed Air Consumption free air/cycle at 80 psi – cu.ft. | 1.04 |

| Steam Inlet/Outlet – npt | DN 15 |

| Steam Pressure – psi(bar) | 100(6.9) |

| Steam Consumption – bhp(kg/h) | 0.99 (15.4) |

| Width – in (mm) | 43.31 (1100) |

| Depth – in(mm) | 41.73 (1060) |

| High – in(mm) | 48.03 (1220) |

| Net Weight – lb(kg) | 700 (315) |

| Shipping Dimensions L/W/H-in (mm) | 50.39/44.88/55.91 1280/1140/1420 |

| Shipping Weight – lb (kg) | 801 (361) |

How to use the pressing machine?

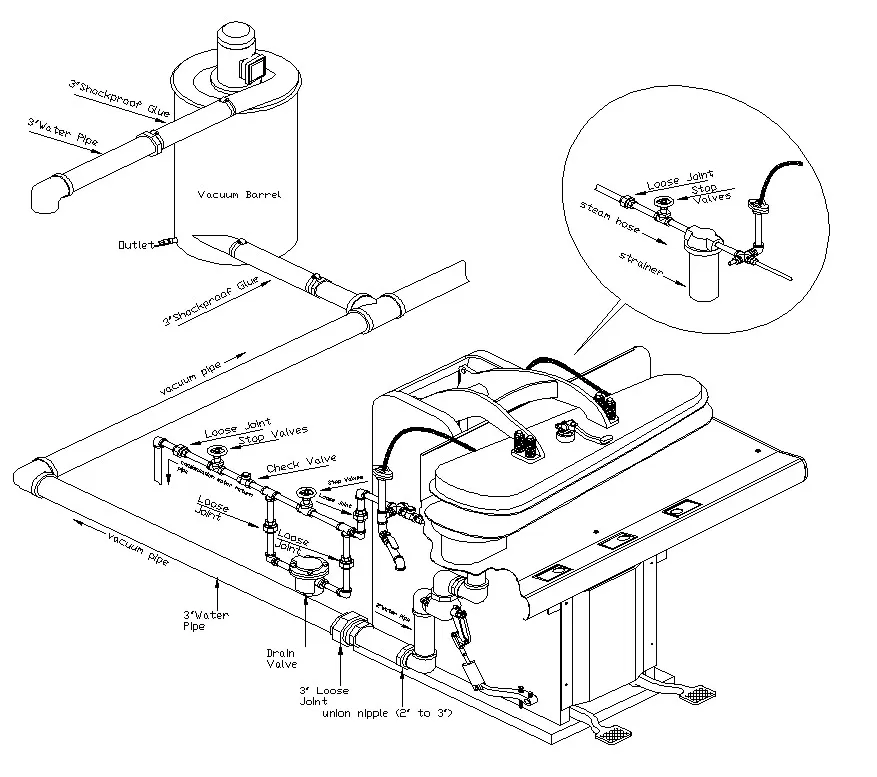

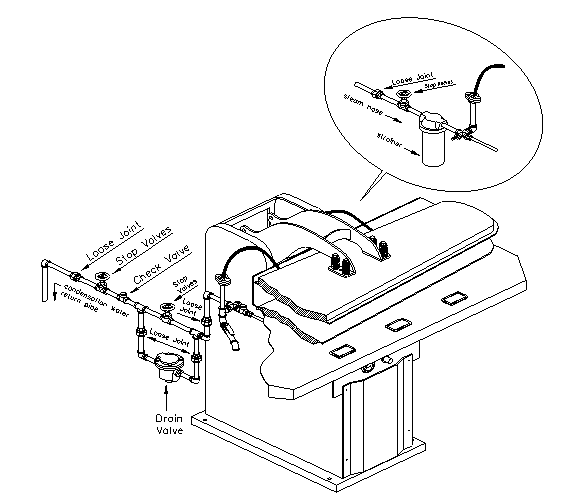

START-UP PROCEDURE:

Do not operate the press until the following five steps.

Open the stop valve in the steam return line.

Open the stop valve slowly, allowing the steam to gradually enter the press.

When operating pressure is reached, open the press drain valve in the return line and drain the condensate into a bucket units steam flows freely. Then close the stop valve tightly.

Open the air compressor.open any air inlet valve to the press; check regulator for maximum 60psi.

What's the Main products of your Company?

We are specilizing in Pressing machine more than 20 years. We offering full serial of Laundry & dryclean pressing machine. Finishing Equipments ,laundry equipments and laundry parts ,laundry accesorries....

Tag: shirt collar and two cuffs pressing machine, laundry pressing equipment

Recommended Products

-

DRYCLEAN NOMEX UTILITY CLOTH PRESS PAD GMX-45 GOLDMAN PRESSI

Model:GMX-45

Weight: -

COLLAR-CUFF-YOKE LAUNDRY PRESS PADS&COVERS GMH-8 GOLDMAN

Model:GMH-8

Weight: -

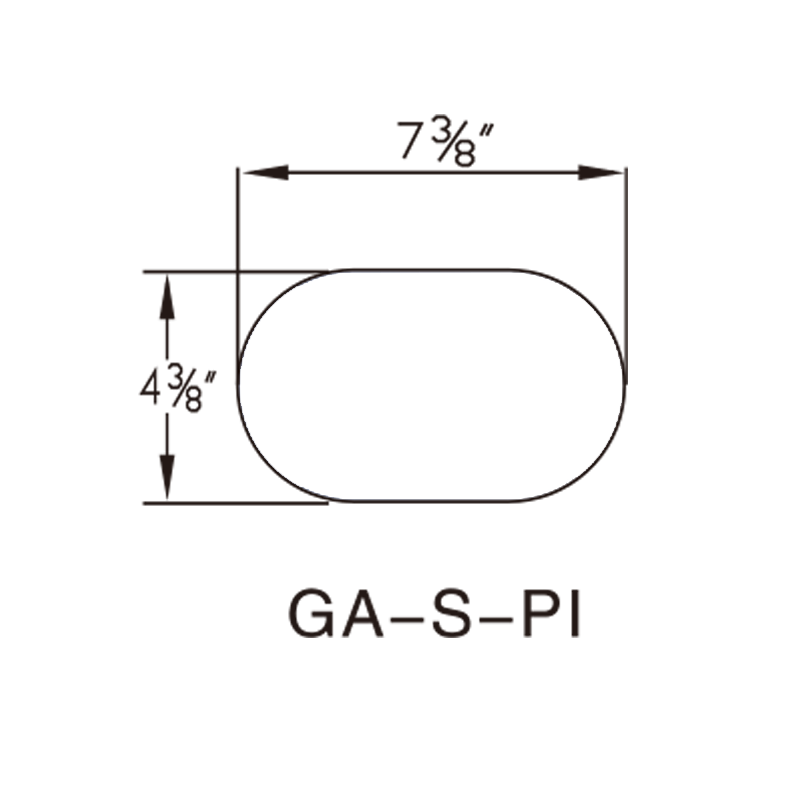

DryCleaning Press Pad GA-S-PI Support For Single Head Single

Model:GA-S-PI

Weight: -

GOLDMAN GM-V3/V6/V8/ V12 Dryset Vacuum

Model:GM-V3/V6/V8/ V12

Weight: -

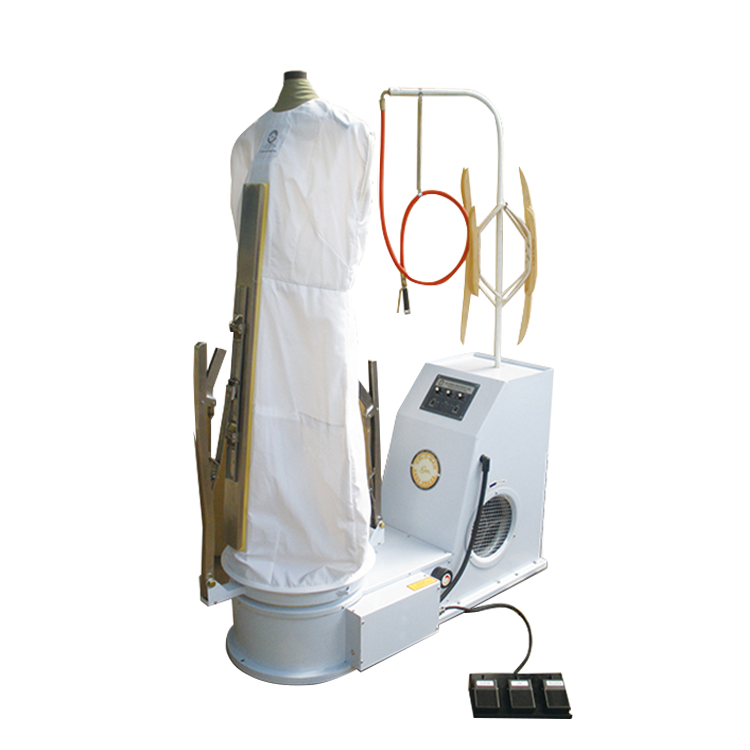

GA-FFM STEAM FINISHER WHITE COLOR

Model:GA-FFM

Weight: -

GOLDMAN PRESS RED CLOSE & GREEN OPEN BOTTON

Model:HV110

Weight: -

ALS 70298701P Orange Dryer Assy Roller Bearing

Model:70298701P

Weight:Dia 63mm 、Thick 26mm -

NEWHOUSE VERTICAL WATER SPRAY GUN

Model:SPRAY GUN

Weight: